FREQUENTLY ASKED QUESTIONS ABOUT THE MAGNORAIL SYSTEM

What scales can the Magnorail System operate in?

As the drive power is under your roadbed it means above the roadbed the system is agnostic so you can place any of your own vehicles in the following gauges: TT, Z, N and HO and now Lego scale, with magnets supplied in the Boxed Slider Starter Kit.

Are the bicycles available in all scales?

No. The bicycle kit (2 cyclists) and Ready to Run (RTR) bicycles are only available in HO Scale.

Do the Ready To Run Bicycles come in starter kits?

No, the RTR series are only available as separate items.

Can I buy cyclist kits separately if I buy a Slider Starter Kit and vice versa for Bicycle Starter kits and extra sliders?

Yes, the standard bicycles with 2 riders (M&F) are available in kit form. All come with magnets for slotting in to your track at your preferred location. The kit needs assembly and painting. The extra slider kit includes magnets for both track and slider attachment.

Can I fit the Magnorail System to my existing layout?

Generally it is difficult to retrofit the Magnorail System as the drive mechanism needs to be embedded under your layout’s roadbed. However with a bit of creative thinking, systems have been added to the inside of a layout.

❖ By way of a single track in front of the back board, then exit behind some scenery, run along the inside of your back board and reappear further along from behind a structure or bush.

❖ Add an extension to the front of your layout with a small return loop.

❖ Add a pond or lake in a “dead" section with pedal boats, ski boats, swans or rowboats.

Check out our YouTube Channel and view the hundreds of Magnorail layout configurations for ideas:

As the drive power is under your roadbed it means above the roadbed the system is agnostic so you can place any of your own vehicles in the following gauges: TT, Z, N and HO and now Lego scale, with magnets supplied in the Boxed Slider Starter Kit.

Are the bicycles available in all scales?

No. The bicycle kit (2 cyclists) and Ready to Run (RTR) bicycles are only available in HO Scale.

Do the Ready To Run Bicycles come in starter kits?

No, the RTR series are only available as separate items.

Can I buy cyclist kits separately if I buy a Slider Starter Kit and vice versa for Bicycle Starter kits and extra sliders?

Yes, the standard bicycles with 2 riders (M&F) are available in kit form. All come with magnets for slotting in to your track at your preferred location. The kit needs assembly and painting. The extra slider kit includes magnets for both track and slider attachment.

Can I fit the Magnorail System to my existing layout?

Generally it is difficult to retrofit the Magnorail System as the drive mechanism needs to be embedded under your layout’s roadbed. However with a bit of creative thinking, systems have been added to the inside of a layout.

❖ By way of a single track in front of the back board, then exit behind some scenery, run along the inside of your back board and reappear further along from behind a structure or bush.

❖ Add an extension to the front of your layout with a small return loop.

❖ Add a pond or lake in a “dead" section with pedal boats, ski boats, swans or rowboats.

Check out our YouTube Channel and view the hundreds of Magnorail layout configurations for ideas:

Do you always have to have a loop to make the Magnorail system work?

No, you can use the system in a lateral manner with the chain just going backwards and forwards in its channeling. As long as the chain stays within the drive unit and automatic stop/start timers are connected to the power supply you could have following scenarios.

A forklift could come out of a warehouse up to a truck and reverse back again.

A small trolley could traverse a boardwalk carrying passengers up and down

A grader or road roller could go backwards and forwards over a patch of roadworks

A container truck could back under a suspended container in a yard

A raft could go up and down a river or creek along the back of a layout

A punt could cross a river and back or alternatively a ferry could cross a lake and return

Of course, most of the above scenarios could use the dogbone return layout or in respect to ferries, just loop through a lake to opposite jetties just using a timer on the power to stop at the halfway mark each circuit.

Do you have to keep the track level.

No. The magnorail track is like a snakes vertebrae able to go up hills and down dales. It can even complete a figure eight with one section going over the other via a bridge or down a culvert. Once again, your imagination is the only limitation and the credibility of what you are operating on the surface is believable.

Can boats run in real water?

As the motive power is under the sea/lake bed, yes you could run boats on a properly sealed lake or river with a film of water - you just need the magnets to be inside the boat or waterproofed.

Can any vehicle be used with the Magnorail System?

Within reason, sliders can be fitted to most wheeled scale models and flat bottomed boats. Once again you can be creative as to how you attach magnets - check out the videos were magnets are directly attached to a vehicles chassis eliminating the need for sliders.

My cyclist has trouble pedalling - how can I fix it?

Sometimes we get questions about bad (or not) pedalling of the cyclist. Usually these problems occur directly after the assembly of the cyclist. Once solved, its often solved definitely. Assembling the cyclist is not an easy job. The parts are very small and the technique of the rolling wheel requires a perfect connection of the components. If problems occur, these are often due to one of the following three causes.

No, you can use the system in a lateral manner with the chain just going backwards and forwards in its channeling. As long as the chain stays within the drive unit and automatic stop/start timers are connected to the power supply you could have following scenarios.

A forklift could come out of a warehouse up to a truck and reverse back again.

A small trolley could traverse a boardwalk carrying passengers up and down

A grader or road roller could go backwards and forwards over a patch of roadworks

A container truck could back under a suspended container in a yard

A raft could go up and down a river or creek along the back of a layout

A punt could cross a river and back or alternatively a ferry could cross a lake and return

Of course, most of the above scenarios could use the dogbone return layout or in respect to ferries, just loop through a lake to opposite jetties just using a timer on the power to stop at the halfway mark each circuit.

Do you have to keep the track level.

No. The magnorail track is like a snakes vertebrae able to go up hills and down dales. It can even complete a figure eight with one section going over the other via a bridge or down a culvert. Once again, your imagination is the only limitation and the credibility of what you are operating on the surface is believable.

Can boats run in real water?

As the motive power is under the sea/lake bed, yes you could run boats on a properly sealed lake or river with a film of water - you just need the magnets to be inside the boat or waterproofed.

Can any vehicle be used with the Magnorail System?

Within reason, sliders can be fitted to most wheeled scale models and flat bottomed boats. Once again you can be creative as to how you attach magnets - check out the videos were magnets are directly attached to a vehicles chassis eliminating the need for sliders.

My cyclist has trouble pedalling - how can I fix it?

Sometimes we get questions about bad (or not) pedalling of the cyclist. Usually these problems occur directly after the assembly of the cyclist. Once solved, its often solved definitely. Assembling the cyclist is not an easy job. The parts are very small and the technique of the rolling wheel requires a perfect connection of the components. If problems occur, these are often due to one of the following three causes.

1. Make sure the upper legs (thighs) are correctly assembled. Pay attention: it’s hard to see, but both thighs are different (mirrored). The thigh section should be assembled as shown in the left view. If it’s upside down (right view), the knee can’t bend enough in the upper position when pedalling.

2. The transparent wheel is a very small injection molded part. This mold has to open to get the product out. So the transparent wheel does have a barely visible seam on the surface. And sometimes there is a small film left on the seam after the product is ejected out of the mold. This film can hinder the wheel from rolling. The film can be removed with a sharp cutter blade.

It is also advisable to use a small pin or nail and ever so slightly widen the hole in the ankle making it easier to to attache the clear wheel - too much though and the food can slip off so be very careful as the studs can break easily if forced.

It is also advisable to use a small pin or nail and ever so slightly widen the hole in the ankle making it easier to to attache the clear wheel - too much though and the food can slip off so be very careful as the studs can break easily if forced.

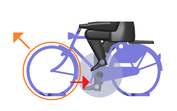

3. It’s possible the legs will bend back in the wrong direction when they can fully stretch. This occurs when the distance between the axis of the hip and the axis of the transparent wheel is too big. Sometimes it’s just a fraction of a millimeter… To reduce this distance, the wheel should be locked well (red arrow). If this doesn’t solve the problem, the front wheel can be bend a bit forward (orange arrow). Doing this, the axis of the transparant wheel will be closer to the axis of the hip when rolling on the surface. This will prevent the legs to be fully stretched.

My cyclist doesn’t pedal at all!

If the cyclist refuses to pedal, please check out the possible following causes.

First, manually check if the transparent wheel rotates flawlessly. If so, there’s likely not enough friction between the wheel and the street surface. Carefully bending out the front fork resolves this problem.

Whenever the wheel has problems every half turn, it can be that you did not assemble the legs correctly. Please refer to the manual and check that you snapped together the upper legs the correct way around. If they are the wrong way around they don’t allow for a full turn of the wheel.

Also please check that there’s no remaining plastic on the inside of the legs.

If none of the above seems to help, it might be that the frame is not straight. Please check and if necessary, rectify it with pliers.

My cyclist doesn’t pedal at all!

If the cyclist refuses to pedal, please check out the possible following causes.

First, manually check if the transparent wheel rotates flawlessly. If so, there’s likely not enough friction between the wheel and the street surface. Carefully bending out the front fork resolves this problem.

Whenever the wheel has problems every half turn, it can be that you did not assemble the legs correctly. Please refer to the manual and check that you snapped together the upper legs the correct way around. If they are the wrong way around they don’t allow for a full turn of the wheel.

Also please check that there’s no remaining plastic on the inside of the legs.

If none of the above seems to help, it might be that the frame is not straight. Please check and if necessary, rectify it with pliers.

How long can I make my Magnorail track?

The most asked question at exhibitions is, what is the maximum length of chain that one motor can drive. There is no simple answer to this question. Starter kits come with 225cm (88.5") of track components which will easily drive a dog-bone or circular layout with several vehicles and bicycles operating. If you view the YouTube Echo Lakes video as linked above, the Rail Trail section uses the components from a bicycle starter set and uses just under 175cm (69") of chain so there was a little left over which was used with another starter set for the Echo Lake section.

In a starter set you get a packet of 9 track component sets comprised of 1x 16cm 1x 4cm straight channels plus 1 x motor housing link of 6cm which leaves 7 motor housing links that you can’t use (ease of production would have caused this anomaly) The total straight channeling = 20cm x 9 = 180cm. You then add the motor housing which clips in to the connecter links which adds a further 5cm of track.

The motor housing and the two links to join the track, total 17 cm giving you a total of 197cm of straight track - able to be curved as you wish.

The addition of the turning circles gives you an extra 33cm - but supplied 30cm of track as there is a bit of slack in the chain once it is all connected into the system. This then gives you the total of 225cm of usable track.

The Echo Lake section which also operates on one motor uses about 240cm of track. This has no particularly sharp curves and copes with 3-4 boats at a time, although when the skiers are attached to the speedboats only 2 other boats can operate or 1 extra speed boat with skiers, any more can cause the drive wheels to slip or not move as too many magnets in sliders attached to vehicles, or bicycles gripping the track, act like brakes..

It all gets down to the physics of drag on the chain between the magnets under the roadbed and those above resulting in the friction of the chain on the track links. Naturally; the less the friction, the longer the length that can be driven. The friction depends on many parameters. The main factors are the number of curves; the variation in height; the covering material and the number of cyclists or vehicle sliders used.

There is 225 cm225 (7.38 feet) track available in a starter set. The chain runs well with one motor on a not too curvy loop using 2 or 3 cyclists or car sliders. This length can even be extended to 2.50 meters (8.2 feet) when the loop is simple. And even a track length of 3 meters (10 feet) is possible, using a set of the return loops. The return loop is specially designed to have very low friction in a 180° curve. They can be used in a so-called dog bone shaped loop: So two straights with a return loop at either end.

In conclusion, the simple answer is that your are not limited by the length of your Magnorail track - it all depends on the physics of your layout and how you wish to operate it!

How can more than one motor work on the chain? .

The Magnorail motors are able to be purchased in the following speeds: Slow, Medium and Fast. The obvious answer to this question is that you must buy the same speed motor for all drives on one particular track. Boat starter kits are set to slow; bicycle starter kits are set to medium; slider starter kits are set to fast. PLEASE NOTE: The Echo lakes boats use a fast motor for the ski boats and jet skis. The standard Magnorail Boat Starter set is made for barges and other slow moving boats. Also note that the upgraded motors in 2022 are not compatible with earlier Motors as they have higher torque. we do stock older versions still so remember to check before you order. The easiest way to recognise the newer models is that they come pre-wired.

How thick is the road bed and what do you use?

Roadbeds vary from styrene sheets to card, brass or photographic board. Obviously the thicker your road bed, the harder the track has to get the magnets to hold and move the sliders and bicycles. Durability of the surface is a key factor. The finish to the roadbed has to endure magnets sliding underneath dragging across it, along with sliders and bicycle pick-ups scratching across the top surface. Avoid joins where possible as bicycles will easily catch on any irregularities and also remember the track magnets will also catch on any irregularities underneath. Generally the thickness should not exceed 0.4mm. The lake bed on Echo Lakes is 0.25mm as an example and the rail trail is a sandwich of photo paper on which a cobblestone effect was printed and then laminated with a Matt Laminating pouch giving a 0.4mm thickness. Humidity and heat can play havoc with the rail trail but that is mainly due the track and adjoining roadbed not level and allows warping to occur. Remember though that the cyclists rely on the friction of the clear centre wheel pressing on the road surface to make the legs move, so resist slick or shiny surfaces. We have proven that the system works with Lego road baseboards, using larger magnets in the vehicles - the slider magnets do not seem capable of penetrating enough to get good contact though.

I have trouble setting the Magnets polarity correctly for the track and bicycles.

This is a key problem for new hobbyists to the Magnorail system. Follow the step-bu-step instructions below for a guaranteed better running system. First get the instruction pamphlet out that came with your kit, or download another copy from this site - see link below

1. remove your magnets from the track and let them click together

2. do the North/South test as per video - not mine but it does the job (https://youtu.be/uYLiuGCPY9c) and colour in the north end on the top magnet with a permanent marker. Carefully slide the two apart and colour north on the bottom magnet -to test, try putting the two black together and they should repel each other

3. Place the magnets in a spare pieces of chain (I have created a permanent template by gluing two chains together and attaching them to a piece of wood so it is always available to test polarity) with the black face showing upwards on both. as per picture 22

4. get the two micro magnets that go on the bicycle wheels and place them on the chain magnets - they will click on with the correct polarity - colour the top of them with the black marker.

5. place your bike on the chain as per picture 23 and secure it with a bit of tape so the bike won’t shift.

6. get a small bit of blutack and put it on a toothpick or plastic knife (not metal) and stick one of the micro magnets on the blutack - (if no blutack just a bit of sticky tape reversed so the tacky side faces out.) so that the black dot is covered

7. put a dot of super glue on the small indentation on the bikes wheel

8. bring the toothpick with the magnet lightly attached, to the front wheel and the magnet should snap in to the indentation - carefully remove the toothpick and blutack and let the glue set - repeat for rear wheel.

9. Remove sticky tape holding the bicycle in place and away you go, so that you can see the black face on the chain magnets and the black face on the bicycle wheels showing that all north faces are on view

NOTE

If you have already stuck the magnets incorrectly on the bicycle wheels, the magnets can be removed if you used super glue, by getting a cotton bud and dab nail polish remover (acetone based product only will work) over the magnet and it will become unstuck.

The most asked question at exhibitions is, what is the maximum length of chain that one motor can drive. There is no simple answer to this question. Starter kits come with 225cm (88.5") of track components which will easily drive a dog-bone or circular layout with several vehicles and bicycles operating. If you view the YouTube Echo Lakes video as linked above, the Rail Trail section uses the components from a bicycle starter set and uses just under 175cm (69") of chain so there was a little left over which was used with another starter set for the Echo Lake section.

In a starter set you get a packet of 9 track component sets comprised of 1x 16cm 1x 4cm straight channels plus 1 x motor housing link of 6cm which leaves 7 motor housing links that you can’t use (ease of production would have caused this anomaly) The total straight channeling = 20cm x 9 = 180cm. You then add the motor housing which clips in to the connecter links which adds a further 5cm of track.

The motor housing and the two links to join the track, total 17 cm giving you a total of 197cm of straight track - able to be curved as you wish.

The addition of the turning circles gives you an extra 33cm - but supplied 30cm of track as there is a bit of slack in the chain once it is all connected into the system. This then gives you the total of 225cm of usable track.

The Echo Lake section which also operates on one motor uses about 240cm of track. This has no particularly sharp curves and copes with 3-4 boats at a time, although when the skiers are attached to the speedboats only 2 other boats can operate or 1 extra speed boat with skiers, any more can cause the drive wheels to slip or not move as too many magnets in sliders attached to vehicles, or bicycles gripping the track, act like brakes..

It all gets down to the physics of drag on the chain between the magnets under the roadbed and those above resulting in the friction of the chain on the track links. Naturally; the less the friction, the longer the length that can be driven. The friction depends on many parameters. The main factors are the number of curves; the variation in height; the covering material and the number of cyclists or vehicle sliders used.

There is 225 cm225 (7.38 feet) track available in a starter set. The chain runs well with one motor on a not too curvy loop using 2 or 3 cyclists or car sliders. This length can even be extended to 2.50 meters (8.2 feet) when the loop is simple. And even a track length of 3 meters (10 feet) is possible, using a set of the return loops. The return loop is specially designed to have very low friction in a 180° curve. They can be used in a so-called dog bone shaped loop: So two straights with a return loop at either end.

In conclusion, the simple answer is that your are not limited by the length of your Magnorail track - it all depends on the physics of your layout and how you wish to operate it!

How can more than one motor work on the chain? .

The Magnorail motors are able to be purchased in the following speeds: Slow, Medium and Fast. The obvious answer to this question is that you must buy the same speed motor for all drives on one particular track. Boat starter kits are set to slow; bicycle starter kits are set to medium; slider starter kits are set to fast. PLEASE NOTE: The Echo lakes boats use a fast motor for the ski boats and jet skis. The standard Magnorail Boat Starter set is made for barges and other slow moving boats. Also note that the upgraded motors in 2022 are not compatible with earlier Motors as they have higher torque. we do stock older versions still so remember to check before you order. The easiest way to recognise the newer models is that they come pre-wired.

How thick is the road bed and what do you use?

Roadbeds vary from styrene sheets to card, brass or photographic board. Obviously the thicker your road bed, the harder the track has to get the magnets to hold and move the sliders and bicycles. Durability of the surface is a key factor. The finish to the roadbed has to endure magnets sliding underneath dragging across it, along with sliders and bicycle pick-ups scratching across the top surface. Avoid joins where possible as bicycles will easily catch on any irregularities and also remember the track magnets will also catch on any irregularities underneath. Generally the thickness should not exceed 0.4mm. The lake bed on Echo Lakes is 0.25mm as an example and the rail trail is a sandwich of photo paper on which a cobblestone effect was printed and then laminated with a Matt Laminating pouch giving a 0.4mm thickness. Humidity and heat can play havoc with the rail trail but that is mainly due the track and adjoining roadbed not level and allows warping to occur. Remember though that the cyclists rely on the friction of the clear centre wheel pressing on the road surface to make the legs move, so resist slick or shiny surfaces. We have proven that the system works with Lego road baseboards, using larger magnets in the vehicles - the slider magnets do not seem capable of penetrating enough to get good contact though.

I have trouble setting the Magnets polarity correctly for the track and bicycles.

This is a key problem for new hobbyists to the Magnorail system. Follow the step-bu-step instructions below for a guaranteed better running system. First get the instruction pamphlet out that came with your kit, or download another copy from this site - see link below

1. remove your magnets from the track and let them click together

2. do the North/South test as per video - not mine but it does the job (https://youtu.be/uYLiuGCPY9c) and colour in the north end on the top magnet with a permanent marker. Carefully slide the two apart and colour north on the bottom magnet -to test, try putting the two black together and they should repel each other

3. Place the magnets in a spare pieces of chain (I have created a permanent template by gluing two chains together and attaching them to a piece of wood so it is always available to test polarity) with the black face showing upwards on both. as per picture 22

4. get the two micro magnets that go on the bicycle wheels and place them on the chain magnets - they will click on with the correct polarity - colour the top of them with the black marker.

5. place your bike on the chain as per picture 23 and secure it with a bit of tape so the bike won’t shift.

6. get a small bit of blutack and put it on a toothpick or plastic knife (not metal) and stick one of the micro magnets on the blutack - (if no blutack just a bit of sticky tape reversed so the tacky side faces out.) so that the black dot is covered

7. put a dot of super glue on the small indentation on the bikes wheel

8. bring the toothpick with the magnet lightly attached, to the front wheel and the magnet should snap in to the indentation - carefully remove the toothpick and blutack and let the glue set - repeat for rear wheel.

9. Remove sticky tape holding the bicycle in place and away you go, so that you can see the black face on the chain magnets and the black face on the bicycle wheels showing that all north faces are on view

NOTE

If you have already stuck the magnets incorrectly on the bicycle wheels, the magnets can be removed if you used super glue, by getting a cotton bud and dab nail polish remover (acetone based product only will work) over the magnet and it will become unstuck.

Why do the track links have different letters on the sprue section when you open the starter pack?

The links are coded mainly for the placement of magnets. The standard bicycles need R x 1 and Q x 1. The ice cream vendor and cargo bikes need three track magnets (supplied) however they require an R + 3 T links to get the correct spacing to allow the bicycle and cart turn corners correctly. The instruction are on the inside lid of tin containing the ice cream vendor. I also use spare links to tension the chain as needed . The tandem bike needs 1 x R and T x 2. Boats Q x 2.

What if I need to change anything once the track is installed.

As an extra hint, I use the turning circles as a means of accessing the chain for fine tuning, as they have a screw to secure the turning wheel. Hide the screw under a little hut or bush and screw your road bed down at this point without gluing or taping it to the layout and if need be you can lift the road bed to re-tension the chain or add a different configuration of magnets or links if needed.

Does the magnet on the slider lift up the magnet on the rail ? In effect lifting the rail causing both top and bottom magnets to rub against the thin roadway?

Its all about physics, which magnetic attraction and friction play a big part.

The plastic chain links are designed to hold the track magnets in place but each link has a small lip about 1mm high either side of the magnet placeholders and these are what actually run against the underside of your roadbed. So yes, the top magnet marginally lifts the chain up to the underside of the roadbed but not the track magnet which should be firmly in place under that 1mm.

The plastic does have less friction than say the metal of the magnet but eventually it will still rub on a surface if operating 8 hours a day for weeks on end, so it is best to have an underside surface with a gloss finish to minimise friction and wear. Always ensure your magnets are firmly in place and below that 1mm plastic lip.

The sliders are made of brass, once again to minimise drag against the surface area. You will notice on my Echo Lakes layout which I take to exhibitions, you can see tracking marks on the roadbed which is the brass leaving a deposit on the roadbed as it mixes with the dust and grime you get in exhibition halls. It should not be as pronounced in home layouts unless you are in a very dusty environment. Also I run up to 5 or 6 vehicles at a time for up to 26 hours continuous use (3x8.5hrs) over a long weekend exhibition and expect a bit more wear and tear than a home layout.

But if only using bicycles this will not be as pronounced

Just as with model trains, you have to clean the track (roadbed) to keep it in pristine condition. As I use a matt plastic laminate for my road surface, this is easily cleaned with a multi purpose cleaner or methylated spirits. I have tried to minimise the tracking by using magnets directly attached to the vehicles, with a piece of stick-on velour/velvet material between the magnet and the roadbed, (I will be doing a video soon on how I made the ride on mower work with this system) making sure the nap or flow of the material flattens as the vehicle goes forward, reducing the friction as it wheels along.

Gary from the UK writes: Hi been watching your builds with the magnorail they are very informative but my problem is the chain when it gets to the motor it rises out of the chain when testing it before road goes down it also happens when a temp road surface is laid any suggestions?

My only thoughts are that

1. You haven’t completely pushed the white plastic plug into the cog tightly enough giving two differing heights between the drive wheels.

2. refit the O rings ensuring they are level with each other

3. make sure you screw down a cover over the drive section - I use a very thin piece of acetate and then put the roadbed over that ensuring that there is a constant pressure over the drive gear -Screws are supplied by Magnorail to either hold down your roadbed or .the acetate.

4. Your chain might be too tight and working against itself - there is a fine line between tight and sloppy but like anything it is just a matter of fine tuning the system.

How can I find where the magnets are in my track?

Magnorail have a magnet finder available to purchase which has fine metal filings that react to the magnets under the roadbed showing clearly their position. Another option is to cut a small window the width of the track, and insert a small piece of thin clear acetate that allows you to view the chain travelling underneath.

The links are coded mainly for the placement of magnets. The standard bicycles need R x 1 and Q x 1. The ice cream vendor and cargo bikes need three track magnets (supplied) however they require an R + 3 T links to get the correct spacing to allow the bicycle and cart turn corners correctly. The instruction are on the inside lid of tin containing the ice cream vendor. I also use spare links to tension the chain as needed . The tandem bike needs 1 x R and T x 2. Boats Q x 2.

What if I need to change anything once the track is installed.

As an extra hint, I use the turning circles as a means of accessing the chain for fine tuning, as they have a screw to secure the turning wheel. Hide the screw under a little hut or bush and screw your road bed down at this point without gluing or taping it to the layout and if need be you can lift the road bed to re-tension the chain or add a different configuration of magnets or links if needed.

Does the magnet on the slider lift up the magnet on the rail ? In effect lifting the rail causing both top and bottom magnets to rub against the thin roadway?

Its all about physics, which magnetic attraction and friction play a big part.

The plastic chain links are designed to hold the track magnets in place but each link has a small lip about 1mm high either side of the magnet placeholders and these are what actually run against the underside of your roadbed. So yes, the top magnet marginally lifts the chain up to the underside of the roadbed but not the track magnet which should be firmly in place under that 1mm.

The plastic does have less friction than say the metal of the magnet but eventually it will still rub on a surface if operating 8 hours a day for weeks on end, so it is best to have an underside surface with a gloss finish to minimise friction and wear. Always ensure your magnets are firmly in place and below that 1mm plastic lip.

The sliders are made of brass, once again to minimise drag against the surface area. You will notice on my Echo Lakes layout which I take to exhibitions, you can see tracking marks on the roadbed which is the brass leaving a deposit on the roadbed as it mixes with the dust and grime you get in exhibition halls. It should not be as pronounced in home layouts unless you are in a very dusty environment. Also I run up to 5 or 6 vehicles at a time for up to 26 hours continuous use (3x8.5hrs) over a long weekend exhibition and expect a bit more wear and tear than a home layout.

But if only using bicycles this will not be as pronounced

Just as with model trains, you have to clean the track (roadbed) to keep it in pristine condition. As I use a matt plastic laminate for my road surface, this is easily cleaned with a multi purpose cleaner or methylated spirits. I have tried to minimise the tracking by using magnets directly attached to the vehicles, with a piece of stick-on velour/velvet material between the magnet and the roadbed, (I will be doing a video soon on how I made the ride on mower work with this system) making sure the nap or flow of the material flattens as the vehicle goes forward, reducing the friction as it wheels along.

Gary from the UK writes: Hi been watching your builds with the magnorail they are very informative but my problem is the chain when it gets to the motor it rises out of the chain when testing it before road goes down it also happens when a temp road surface is laid any suggestions?

My only thoughts are that

1. You haven’t completely pushed the white plastic plug into the cog tightly enough giving two differing heights between the drive wheels.

2. refit the O rings ensuring they are level with each other

3. make sure you screw down a cover over the drive section - I use a very thin piece of acetate and then put the roadbed over that ensuring that there is a constant pressure over the drive gear -Screws are supplied by Magnorail to either hold down your roadbed or .the acetate.

4. Your chain might be too tight and working against itself - there is a fine line between tight and sloppy but like anything it is just a matter of fine tuning the system.

How can I find where the magnets are in my track?

Magnorail have a magnet finder available to purchase which has fine metal filings that react to the magnets under the roadbed showing clearly their position. Another option is to cut a small window the width of the track, and insert a small piece of thin clear acetate that allows you to view the chain travelling underneath.